Heat Press Adhesives

$2.00 – $10.50

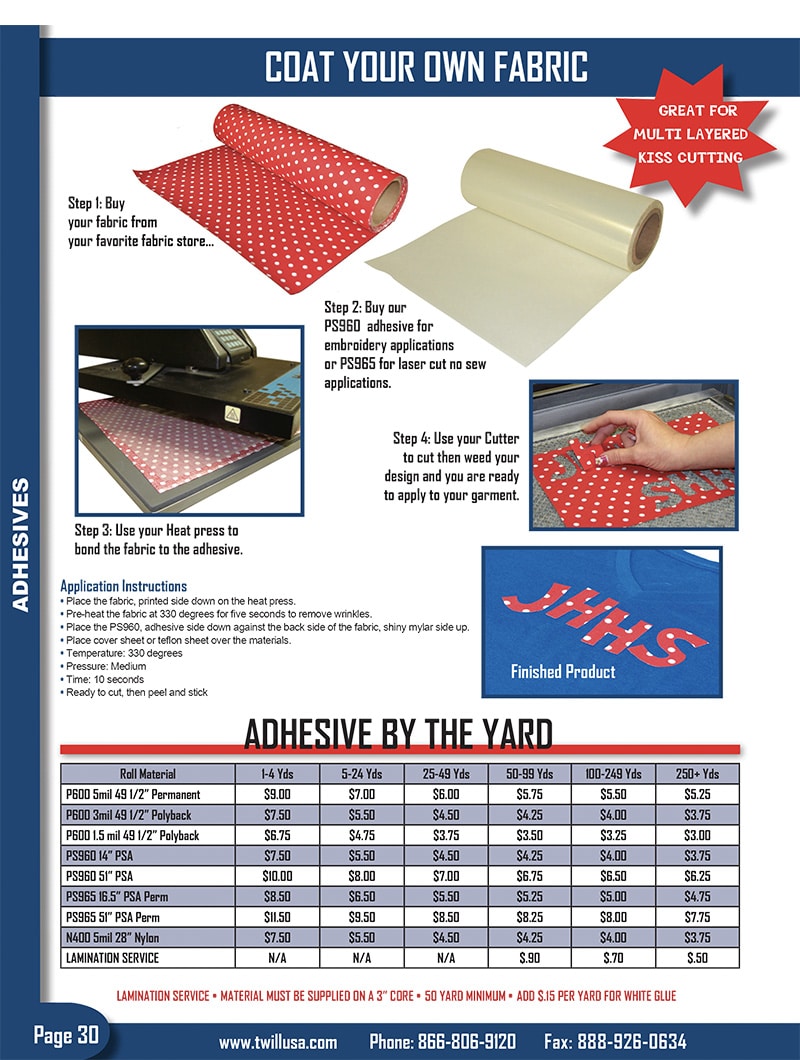

Our proprietary Hot-Melt Adhesives are manufactured in-house and can be used to coat your own fabric. PS960 adhesive is perfect for embroidery applications, whereas PS965 is intended for laser-cut no-sew applications. Use your heat press to bond fabrics to the adhesive, then use your craft cutter or desktop plotter to cut — then weed — your designs. Works with any fabric.

*** Discounts for bulk/tiered pricing auto-apply in the Cart. ***

| PRICE PER YARD | ||||

| ROLL MATERIAL | 1–4 | 5–24 | 25–49 | 50+ |

| P600 5-Mil 16.5″ Permanent | $10.00 | $6.75 | $5.75 | $5.25 |

| P600 3-Mil 16.5″ Polyback | $9.00 | $5.25 | $4.50 | $4.00 |

| P600 1.5-Mil 16.5″ Polyback | $8.25 | $4.75 | $4.00 | $3.50 |

| PS960 14″ PSA | $9.25 | $7.00 | $5.75 | $5.50 |

| PS965 SHEET (9″ X 12″) | $2.00 | $2.00 | $2.00 | $2.00 |

| PS965 16.5″ PSA PERM | $10.50 | $8.25 | $7.25 | $7.00 |

| N400 5-Mil 28″ Nylon | $9.25 | $7.00 | $5.75 | $5.50 |

Product Details

Often referred to as a "stabilizer," our products feature either a paper- or Mylar-backed sheet of heat-activated adhesive and sold in rolls by the yard. It requires low temperature and short pressing times, which enable a wide range of fabrics to bond to it. These solid sheets of adhesive allow for edge-to-edge coverage for applique shapes on quilts, wall hangings and attire, without puckering or bunching. NOTE: These are the same adhesive systems used to coat Acrylic Felt and Sports Twill, as well as our other specialty films for the HTV marketplace.

- PSA — PSA stands for "Pressure Sensitive Adhesive." Our PSA features a clear Mylar backing. This peel-and-stick adhesive holds applique in place for sewing. Our U.S. patented formula prevents broken threads and gummed-up needles. Repositionable. Perfect for 2-color applications and Kiss Cutting. Must be sewn to prevent fraying.

- Polyback — The thermal adhesive backing provides stability for cutting and sewing on garments. The polyester-based coating has no PVC and can be cut on plotters, dies, lasers or even hand-cut. Must be sewn to prevent fraying.

- Permanent — Heat seal adhesive designed to be laser-cut and heat-pressed onto garments without sewing. This non-PVC adhesive will not burn from laser cutting while it simultaneously prevents fraying.

- PSA Permanent — The #1 choice for laser cutters. It can be used for no-sew applications or it can be embroidered onto garments as an applique. Perfect for Kiss Cutting 2-color designs. Repositionable. Works with all laser cutters and applications.

- Uncoated — No adhesive backing. Just the fabric.

Application Info

Recommended for use with the following fabrics: Cotton, Polyester, Acrylic, Nylon and Poly-Cotton Blends. Place the fabric printed-side down on the heat press. Then, place the PS960 adhesive-side down against the back of the fabric, shiny Mylar-side up.

- Temperature: 330°F

- Time: 10 seconds

- Pressure: Medium

HINT: Run a lint roller over the transfer area (on the garment) to remove any loose threads or stray fibers. Preheat your garment for 5 seconds. Place the transfer onto the garment, then place a cover sheet over the design. Time, temperature and pressure may vary if using an iron instead of a heat press machine.

Place An Order

Formed in 1993 as a Division of Specialty Adhesive Film Co., our Mission has always been to provide the #1 Heat Transfer Products for the sports apparel industry. We have been awarded multiple U.S. patents (see About Us) for the methods and materials used to manufacture specialty films, fabrics and Hot-Melt Adhesives. We pledge to provide our clients with exceptional products and continued commitment to innovation, technology, and low prices. TwillUSA.com offers dozens of Heat Transfer Materials in hundreds of colors, plus $10.00 flat-rate shipping on orders delivered to CONUS.

Heat Press Adhesive FAQs

Do You Have Adhesive To Embroider Patches?

To bond an embroidered patch to garments, use our P600 5-Mil Permanent Hot-Melt Adhesive. Apply the P600 adhesive to the back of the patch, trim off any excess material, and it's ready to heat press and fuse.

Which Adhesive Is Best For Sewing Applications?

The PS960 is the best adhesive to use to keep fabric for sewing applications in place. It utilizes a peel-and-stick pressure sensitive adhesive ("PSA") with a needle glide additive to prevent gummed-up needles.

Which Types of Fabric Does Your Adhesive Bond To?

Our proprietary Hot-Melt Adhesives permanently bond to all types of fabric except for nylon and leather. It will adhere to cotton, polyester, poly-cotton, acrylics like Sports Felt and performance fabrics. The adhesive can also be used as a temporary bond in order to sew.

Is This Product Similar to Heat'n Bond And Wonder-Under?

Our P600 Hot-Melt Adhesive is similar to both Heat'n Bond and Wonder-Under. However, the P600 is a solid hot-melt film while Wonder-Under is a non-woven web. Consequently, the film features more adhesive than a web of the same thickness and is more durable as a result.

Is Sewing Required After Cutting Your PSA Permanent Backing?

Our PS965 PSA Permanent backing was designed so that sewing on the garment is unnecessary. It features a dual peel-and-stick component to hold it in place and a hot-melt component that permanently fuses to the garment upon heat pressing.

Does Your Adhesive Have A Backing So That I Can Cut It On My Craft Cutter?

P600, PS960 and PS965 can be used with a multitude of cutters depending on the application. The PS960 and PS965 have Mylar backings that allow plotters to Kiss Cut through to the liner. It also has a peel-and-stitch feature that holds the applique in place for permanent bonding (PS965) or for embroidery or sewing (PS960). The P600 is intended only for Silhouette or Cricut desktop cutters or can be hand-cut with scissors.

Aurora, Indiana, U.S.A. (HQ)

7080 Chartom Circle

Aurora, IN 47001

Phone: (866) 806-9120

Fax: (812) 926-0634